A Practical Guide to Free-Energy Devices Author: Patrick J. Kelly Chapter 9: Passive Systems |

Hans Coler. A German naval captain called Hans Coler invented a COP>1 generator in 1925. He called this device the ‘Stromerzeuger’ and for a few watts from a dry battery it provided 6 kW continuously. He was refused development support because it was “a perpetual motion machine”.

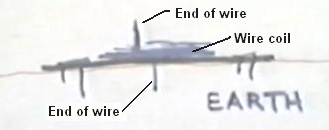

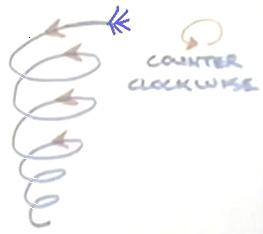

Hans also invented a passive device which he called the ‘Magnetstromapparat’. His unit required very careful and slow adjustment to get it operating but when it started it continued on test in a locked room for three months of continuous operation. Nobody, including Hans, seems any too sure how this device works but it is presented here in case you wish to research it further. It comprises six bar magnets wound as shown here. Some are wound in a clockwise direction when looking at the North pole and these are called “Right” those wound in an anticlockwise direction are called “Left”:

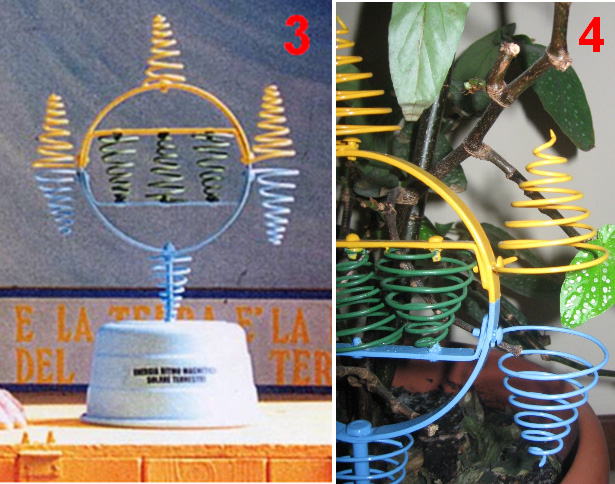

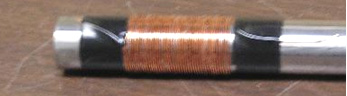

These six magnets are arranged in a hexagon and wired as shown here:  And the schematic diagram is:  One extremely interesting feature of this passive device is that it has been witnessed producing 450 mV for several hours; it was capable of developing up to 12 Volts. The witnesses were quite sure that it was not picking up radio or mains input. So, what was it picking up? With magnets as the key component, it seems clear that it is the zero-point energy field which is being accessed, but clearly, the access represents a vanishingly small percentage of the actual power available To operate the device, the switch is left in the open position, the magnets are moved slightly apart and the sliding coil set into various positions with a wait of several minutes between adjustments. The magnets are then separated still further and the coils moved again. This process is repeated until at a critical separation of the magnets, a voltage is developed. The switch is now closed and the process continued more slowly. The voltage then builds up to a maximum which is then maintained indefinitely. The position of the apparatus in the room and the orientation of the device had no effect on the output. The magnets were selected to be as nearly equal in strength as possible and the resistance of the magnet and coil were checked after winding to make sure they were as nearly equal as possible (about 0.33 ohms). As far as I am aware, nobody has managed to produce a successful replication of either of the Hans Coler devices, which is a pity since it seems clear that these devices have the potential to indicate the nature of the zero-point energy field and possibly, how it may be tapped efficiently. A very neat construction of the Coler ‘Magnetstromapparat’ by an unknown German experimenter is shown below - I’m afraid without permission as I have no idea who he is or how to contact him to ask his permission. The quality of workmanship is impressive and the result is a very professional looking device. Notice the sliding coil arrangement at the bottom left with one coil being positioned closely inside another and held in place where the experimenter chooses:  Thomas Trawoeger. One thing which is quite certain, and that is the fact that at this point in time, our technical know-how has not yet encompassed the zero-point energy field properly. It is by no means obvious how the Hans Coler device operates, and if we understood the technology properly, we would be able to say with certainty, exactly how and why it operates, and ways to improve it would be obvious. As it is, all we can do is look at it and wonder, possibly try a few experiments, but the bottom line is that we do not yet understand it. This is the normal situation in the early days of any new field of technology.  It is also quite usual for pioneers in any new field to encounter a good deal of opposition, mistrust, and generally disheartening treatment from other people. That is certainly the case for Thomas Trawoeger from Austria, who has progressed well in the passive energy field. He has suffered repeated web-based attacks with his display material being destroyed and web sites being made inoperable. So, what makes some people so afraid of Thomas? The answer is that he is experimenting with shapes. That doesn’t sound too terrible does it? Well, it certainly bothers some people, which suggests that he must be on the verge of uncovering a mechanism for drawing serious amounts of power from the zero-point energy field. Thomas is by no means the first person to examine this area, but he is one of the first to consider drawing serious amounts of electrical energy from the local environment using shape and an appropriate detector. Obviously, this is the same area that Hans Coler was investigating, and it appears that Thomas has managed to tap a continuous 8 watts of electrical energy using a wholly passive device. As we are not all that familiar with this type of technology, we tend to dismiss it as being a “crackpot” area, not worthy of investigation by serious scientists. It is actually, very far from being that in reality, and it just indicates our serious lack of technical understanding if we dismiss it out of hand. Two hundred years ago, the idea of a television set would definitely have been considered a “crackpot” pipe dream, far, far away from reality. Today, any schoolchild would be horrified at the thought of a TV set being considered “crackpot”. So, what has changed? Only our level of technology, nothing else. In another two hundred years time, when the zero-point energy field is fully understood, people will look back with a smile at the though of people like us who didn’t know how to draw any amount of energy, freely from the environment, and they will laugh at the thought of burning a fossil fuel to produce energy from a chemical reaction. That, of course, does not help us at all in this time of our ignorance, and we still have to deal with the sort of people who thought that the horse-drawn cart would never be superseded. The scientific method has been established for a long time now. Essentially, observations are made, experiments are performed and a theory is produced which fits all of the known facts. If additional facts are discovered, then the theory needs to be modified or replaced by another which includes all of the new facts. Established scientists find it difficult to adhere to the scientific principle. They are afraid of losing their reputation, their job or their funding and so are reluctant to investigate any new facts which indicate that some of their best-loved theories need to be revised. Fortunately, not being in the business, we can take new facts on board without any problem. In the light of what certain shapes do, this is just as well. Let us see if we can put this in perspective. Consider an intelligent, well-educated person living several hundred years ago. Looking skyward at night, he sees the stars. At that time, the theory was that the stars were fixed to a ‘celestial sphere’ which rotates around the Earth. That was a perfectly good theory which matched the known facts of the time. In fact, the concept matches the observed facts so well that some people who teach Astro Navigation to sailors still find it to be useful in teaching the subject today. If you told the average person of those days, that the stars were not very small but very large indeed, that the Earth is orbiting around the Sun and in fact, the Sun is one of those ‘tiny’ stars, then you would have been considered one of the ‘lunatic fringe’. Next, if you were to tell that person that there were invisible forces passing through the walls of his house and even through him, he would most certainly rate you as a bona fide member of the ‘lunatic fringe’. However, if you then took several compasses into his house and demonstrated that they all pointed in the same direction, he might start to wonder. Now, just to really establish your membership of the ‘lunatic fringe’ you tell him that one day there will be invisible rays passing through the walls of all buildings and that these rays will allow you to watch things happening on the other side of the world. Finally, to complete the job, you tell him that there is a substance called uranium, and if he were to carry a piece around in his pocket, it would kill him by destroying his body with invisible rays. Today, school children are aware of, the Solar System, magnetic lines of force, television and X-rays. Further, as the scientific theory has caught up, these children are not considered part of the ‘lunatic fringe’ but this knowledge is expected of them as a matter of course. The only thing which has changed is our understanding of the observed universe. At the present time, we are faced with a number of observations which do not fit in with the scientific theories of some of the current educational establishments. If we consider these things seriously, we run the risk of being considered part of the ‘lunatic fringe’ until such time as scientific theory catches up with us again. So be it, it is better to examine the facts than to pretend that they don’t exist. Present theory has worked well enough up to now, but we need to take on board the fact that since it does not cover all of the facts, it needs to be extended or modified. So, what observed facts are causing a problem? Well: 1. In Quantum Mechanics it has been found that some pairs of particles are linked together no matter how far apart they are physically. If you observe the state of one of the pair, the state of the other changes instantly. This happens far, far faster than the speed of light and that does not fit neatly into present theory. 2. If a substance is cooled down to Absolute Zero temperature, it should be completely motionless, but that is not the case as movement can be observed. This movement is caused by external energy flowing into the frozen material. That energy, observed at Absolute Zero temperature is called ‘Zero-Point Energy’. So where does that fit into the theory? 3. There are several devices which are self-powered and which are capable of powering external loads. These things appear to act in defiance to the Law of Conservation of Energy. 4. The Aspden Effect (described below) indicates that current theory does not cover all of the facts. 5. It is now known and fully accepted by science that more than 80% of our universe is composed of matter and energy which we cannot see. 6. Even though our Sun is losing some five tons of mass per second, it radiates more energy than can be accounted for by the fusion of the amount of matter which would cause this loss of mass. 7. The inner core of the Earth is hotter than present theory would expect it to be. These things indicate that there is something in our universe which is not properly covered by current theory. The present theory thinks of space as being a volume which contains no matter, other than perhaps, a tiny amount of inter-stellar dust. And while space can be traversed by radio waves and many other types of radiation, it is essentially empty. This concept is definitely not correct. All of the odd observed facts suddenly fit in if we understand that there is an additional field which streams through all of space and passes unnoticed through all matter. This field is composed of particles so tiny that they make an electron appear enormous. These particles may in fact be the ‘strings’ of String Theory. What is sure, is that this stream of matter contains virtually unlimited energy. It is the energy seen at Absolute Zero as it is continually streaming in from outside the cold area. It flows to us from every direction and the sun being a major source of it, augments the flow we receive during the daytime. This accounts for the variations seen by T. Henry Moray during the night when the energy he was picking up decreased somewhat. This matter stream acts like a very dense gas except for the fact that effects in it have effectively zero propagation time. This accounts for the widely separated particles having what appears to be simultaneous reactions to a stimulus. Einstein’s idea of the speed of light being an absolute maximum is definitely wrong, as has been demonstrated in the laboratory. In the early stages of investigating a new field, it can be quite difficult to work out how to approach it, especially if the field is entirely invisible and can’t be felt. The same situation was encountered in the early days of magnetism as lines of magnetic force are not visible and cannot be felt. However, when it was observed that iron was affected by magnetism, a mechanism was discovered for displaying where the invisible lines are located, by the use of iron filings. Interestingly, the presence of an iron filing alters the lines of magnetic force in the area as the lines “have a preference for” flowing through the iron. Also, the iron filings used in school demonstrations do not show the actual lines of magnetic force correctly as they themselves become tiny magnets which alter the lines of force which they are supposed to be showing. We are still in the early stages of investigating the Zero-Point Energy field, so we have to consider anything which has an effect on this invisible field. One observed effect was found by Harold Aspden and has become known as the ‘Aspden Effect’. Harold was running tests not related to this subject. He started an electric motor which had a rotor mass of 800 grams and recorded the fact that it took an energy input of 300 joules to bring it up to its running speed of 3,250 revolutions per minute when it was driving no load. The rotor having a mass of 800 grams and spinning at that speed, its kinetic energy together with that of the drive motor is no more than 15 joules, contrasting with the excessive energy of 300 joules needed to get it rotating at that speed. If the motor is left running for five minutes or more, and then switched off, it comes to rest after a few seconds. But, the motor can then be started again (in the same or opposite direction) and brought up to speed with only 30 joules provided that the time lapse between stopping and restarting is no more than a minute or so. If there is a delay of several minutes, then an energy input of 300 joules is needed to get the rotor spinning again. This is not a transient heating phenomenon. At all times the bearing housings feel cool and any heating in the drive motor would imply an increase of resistance and a build-up of power to a higher steady state condition. The experimental evidence is that there is something unseen, which is put into motion by the machine rotor. That “something” has an effective mass density 20 times that of the rotor, but it is something that can move independently and its movement can take several minutes to decay, while in contrast, the motor comes to rest in a few seconds. Two machines of different rotor size and composition reveal the phenomenon and tests indicate variations with time of day and compass orientation of the spin axis. One machine, the one incorporating weaker magnets, showed evidence of gaining magnetic strength during the tests which were repeated over a period of several days. Nikola Tesla found that uni-directional electric pulses of very short duration (less than one millisecond) cause shockwaves in this medium. These Radiant Energy waves passed through all materials and if they strike any metal object, they generate electrical currents between the metal and ground. Tesla used these waves to light glass globes which had just one metal plate. These lights do not have to be near the source of the Radiant Energy waves. He discovered many other features of these ‘longitudinal’ waves but one which is of particular interest is that when using his famous Tesla Coil, the waves produced visible streamers which showed what they were doing. What they were doing was running up the outside of the long inner wire coil, not through the wire, mark you, but along the outside of the coil, and when they reached the end of the coil, they continued on out into the air. Interestingly, Tesla believed that this flow of energy “preferred to run along the corrugations of the outside of the coil”. That is to say, somewhat like magnetic lines showing a preference for running through iron, this energy field shows a preference for flowing along certain physical shapes. Thomas Henry Moray developed equipment which could tap up to fifty kilowatts of power from this field. There are two very interesting facts about Moray’s demonstrations: Firstly, the valves which he used to interact with the field, had a corrugated cylindrical inner electrode - an interesting shape considering Tesla’s opinion on the corrugated outer surface of his coil. Secondly, Moray frequently demonstrated publicly that the power obtained by his equipment could flow uninterrupted through sheet glass while powering light bulbs. Quite apart from demonstrating that the power was definitely not conventional electricity, it is very interesting to note that this power can flow freely through materials. I venture to suggest that Moray’s power was not flowing through the wires of his apparatus but rather it was flowing along the outside of the wires, or perhaps more accurately, flowing along near the wires. Edwin Gray snr. managed to draw large amounts of power from a special tube designed by Marvin Cole. The tube contained a spark gap (like that used by Tesla) and those sparks produced Radiant Energy waves in the Zero-Point Energy field. He managed to collect energy from these waves, very interestingly, by using perforated (or mesh) cylinders of copper surrounding the spark gap. His 80 horsepower electric motor (and/or other equipment such as light bulbs) was powered entirely from energy drawn from the copper cylinders while all of the electrical energy taken from the driving battery was used solely to generate the sparks. It is very interesting to note that Tesla, Moray and Gray all indicate that corrugated or rough-surface cylinders seem to direct the flow of this energy. Dr Harold Aspden also indicates that once the field is set in motion in any locality, it tends to continue flowing for some time after the influence which is directing it is removed. Please remember that we are starting to examine a new field of science, and while we know a very limited amount about it at this point in time, at a later date, every schoolchild will be completely familiar with it and find it hard to believe that we knew so little about it, at the start of the twenty-first century. So, at this time, we are trying to understand how energy can be extracted from this newly discovered field. The indications are that the physical shape of some objects can channel this energy. If you think about it, you suddenly realise that we are already familiar with shape being important in focusing energy. Take the case of a magnifying glass. When the sun is high in the sky, if a magnifying glass is placed in just the right position and turned in just the right direction, then it can start a fire. If the principles behind what is being done are not understood, then the procedure sounds like witchcraft: 1. Make a specially shaped object with curved faces, out of a transparent material 2. Discover the ‘focal-length’ of the object 3. Wait until Noon 4. Place some kindling on the ground 5. Position the object so that it looks directly at the sun 6. The kindling will catch light without you even having to touch it.  Sounds like something out of a book on magic, doesn’t it? Well, you need to know all about that if you want to pass any basic physics examination, and it comes in under the title of “Optics”. Please notice that the shape of the lens is vital: it must have a convex face on both sides. Also, the positioning is vital, the lens must be exactly its focal length away from the kindling material: a little too near or a little too far away and it just does not work. Magic? Well it may seem like it, but no, it is just scientific understanding of the nature of radiation from the sun. Take the case of a satellite dish. This familiar object needs to be an exact shape to work well. It also needs to be made of a material which reflects high-frequency radio waves. Make one out of wood and it will look just the same but it will not work as the TV transmission will pass straight through the wood and not be reflected on to the pick-up sensor connected to the television set. However, obvious and all as this is, it still did not cut any ice with the patent office in Czechoslovakia on the 4th November 1949. A radio engineer called Karel Drbal turned up with a patent application for a cardboard pyramid shape which kept razor blades sharp and was promptly told to get lost. The patent authorities demanded that he have a theory to show how the device worked. Karel was not particularly put out, and spent years investigating before he determined a theoretical basis for the device. He returned to the patent office, much to the disbelief of the Chief Patent Officer. He was granted his patent, not because his theory was compelling, but because the Chief Patent Officer took a pyramid home and tested it with his own razor blades. When his practical tests confirmed that the pyramid did exactly what Karel claimed, he was granted Patent No. 91304, “Method of Maintaining Razor Blades and the Shape of Straight Razors” and here is a translation: Office For Patents And Inventions Published August, 1959 Patent File Number 91304 The right to use this invention is the property of the State according to Section 3, Paragraph G, Number 34/1957 Karel Drbal, Prague Method of Maintaining Razor Blades and the Shape of Straight Razors. Submitted 4 November, 1949(P2399-49) Patent valid from 1 April, 1952 The invention relates to the method of maintaining of razor blades and straight razors sharp without an auxiliary source of energy. To sharpen the blades therefore, no mechanical, thermal, chemical or electrical (from an artificial source) means are being used. There are various mechanical sharpening devices being used up to now, to sharpen used razor blades. The blade is sharpened by crude application of sharpening material, which always results in certain new wear of the blade during the sharpening process. Furthermore, it is known that the influence of an artificial magnetic field improves the sharpening of razor blades and straight razors, if their blades are laid in the direction of the magnetic lines. According to this invention, the blade is placed in the earth's magnetic field under a hollow pyramid made of dielectric material such as hard paper, paraffin paper, hard cardboard, or some plastic. The pyramid has an opening in its base through which the blade is inserted. This opening can be square, circular, or oval. The most suitable pyramid is a four sided one with a square base, where one side is conveniently equal to the height of the pyramid, multiplied by pi /2. (which is pi or 3.14 / 2). For example, for the height of 10 cm, the side of 15.7 cm is chosen. The razor blade of a straight razor is placed on the support made also of dielectric material, same as the pyramid, or other such as cork, wood, or ceramics, paraffin, paper, etc. Its height is chosen between 1/5 and 1/3 of the height of the pyramid, this support rests also on a plane made of dielectric material. The size of this support should be chosen as to leave the sharp edges free. Its height could vary from the limits stated above. Although it is not absolute necessary, it is recommended that the blade be placed on the support with its sharp edges facing West or East respectively, leaving its side edges as well as its longitudinal axis oriented in the North / South direction. In other words to increase the effectiveness of the device it is recommended lie in essence in the direction of the magnetic lines of the horizontal component of the earth's magnetism. This position improves the performance of the device, it is not however essential for the application of the principle of this invention. After the blade is properly positioned, it is covered by the pyramid placed in such a way that it’s side walls face North, South, East, and West, while its edges point towards North-West, South-West, South-East, and North-East. It is beneficial to leave a new blade in the pyramid one to two weeks before using it. It is essential to place it there immediately after the first shave, and not the old, dull one. But it is possible to use an old one, if it is properly resharpened. The blade placed using the method above is left unobstructed until the next shave. The west edge should always face West. It improves the sharpening effect. Example: When this device was used, 1778 shaves were obtained using 16 razor blades, which is 111 shaves per blade on the average. The brand used was "Dukat Zlato" made in Czechoslovakia. The lowest count was 51, the highest was 200. It is considered very easy to achieve up to 50 shaves on the average. (for a medium hard hair). The following shows how the invention could save both valuable material and money. One of the razor blades mentioned above, weighs 0.51 grams. We will consider 50 shaves on average when placed in the pyramid against 5 shaves when it is not. It is obvious that the number of shaves, degree of wear, and the ability to regenerate the dull edge depends on the quality of the material, quality of sharpening process, and hardness. ....given that the numbers are averages and could be in fact much better. In the course of the year one therefore uses 73 razor blades without the aid of the pyramid while only eight razor blades while using the pyramid. The resulting annual saving would be 65 razor blades or 33.15 grams of steel per person. Only the pyramid shape has been used for this invention, but this invention is not limited to this shape, as it can cover other geometric shapes made of dielectric material that was used in accordance with the invention. And that this shape also causes regeneration of sharp edges of shaving blades by lowering of stresses and reducing the number of defects in the grids of crystal units, in other words recovering and renewing the mechanical and physical properties of the blade. This is interesting, as it confirms by independent test that a pyramid shape produces an effect, even if it is not possible to say with absolute certainty what exactly the effect is and how exactly the pyramid shape manipulates that energy. Thomas Trawoeger has produced a video of a pyramid which he constructed. The video commentary is in German and it shows a computer fan being operated when connected to his pyramid which looks like this:  Sceptics will immediately say that as there are wires connected to the device, that the power for the fan is being fed through those wires, even though they appear to be connected to monitoring equipment. This is possible, but in my opinion, it is not actually the case. The pick-up used is shown here:  It should be remembered that these pictures are quite old and all inventors keep working on their inventions in an effort to improve their operation and to investigate the effects caused by alterations. At the close of 2007 the design has progressed considerably and now features a number of most unusual things ranging from construction to orientation. This forum is working on replicating this design thanks to the generosity of Thomas Trawoeger who speaks German and the exceptional work of Stefan Hartmann who has produced an English translation and who hosts the web site. The following is an attempt to present the basic information from that forum in a clear and concise manner, but I recommend that you visit and contribute to the forum if you decide to experiment with this design. The frame of the pyramid is not the same shape as the well-known Egyptian pyramids and has a sloping face some 5% longer than those in Egypt. The materials used in constructing the pyramid are very important. The frame is made of 20 mm x 20 mm x 2 mm square-section steel tube. While the exact size of the pyramid is not critical, the exact proportions are critical. The base must be exactly square, with each side of the base being exactly the same length, 1 metre in this case. The sloping sides are exactly the same length as the base pieces being 1 metre long also. Eight one-metre lengths of steel section will therefore be needed for building the frame. The sides of the pyramid need to be covered with a rigid sheet and here again, the material used is critical, with only gypsum/paper boards (plasterboard with no foil) being satisfactory - other materials just don’t work. If no sides are added, then the pyramid is very difficult to adjust to get proper operation. When the frame has been constructed, its is positioned in a most unusual way being forty-five degrees away from the conventional positioning of a pyramid. This sets this pyramid so that one pair of corners face North - South, and the frame should be connected to a good electrical ground as shown here:  The pick-up is constructed from 12 mm outside diameter copper pipe and fittings and is hard soldered together. It has an overall size of 120 mm x 100 mm hard soldered together as shown here:  This frame of copper piping is not assembled as shown straight off as there is a requirement for a long graphite rod, 2 to 3 mm in diameter, to be positioned vertically inside each vertical leg of this frame and that can’t be done after assembly. So the bottom section is assembled as one piece, and the top section is assembled separately with the graphite rods sticking down out of the T-sections, held in place by their wires and insulating plugs. The graphite rods can be bought from art materials supply shops.  The very fine filter-grade quartz sand filling for the tubes is inserted and the graphite rods carefully positioned so that they do not touch the side walls of the vertical copper tubes, and the two parts joined by hard soldering:  The left hand side hole in the copper pipe is used to inject a 5% salt / water solution, using a hypodermic syringe, until the water starts to come out of the hole at the right hand side. The right hand side hole is 5 mm lower down than the one on the left. Next, the wires are bent around to produce a 9-turn coil with a 25 mm diameter, around the vertical copper pipes. The windings are in opposite directions on the opposite sides of the frame:  Next, a ten-plate capacitor is made from copper sheets 1 mm thick. As copper is very expensive, the copper plates can be produced from spare lengths of copper pipe, cut along the axis and flattened careful to produce a smooth, unmarked surface 70 mm x 35 mm in size. The plates are stacked and accurately aligned, and a hole is drilled 1 mm off-centre. Then each alternate plate is turned around to produce two sets of plates bolted together with a 6 mm diameter plastic bolt, 1 mm thick plastic washers and a plastic nut. A plastic threaded rod and a plastic nut can be used instead of a plastic bolt. Because the hole is not quite central, the plates stick out at each end, giving clearance for attaching the plates together with the copper wire coming out of the copper pipe framework:  The capacitor is positioned inside the copper pipe frame and held in place by the strength of the 2.5 mm thick copper wire coil around the vertical pipes in the frame:  The pick-up sensor is now attached to the pyramid frame. Using a non-conductive cord, it is suspended by the top lug and it’s orientation controlled using the lower two lugs. The positioning in the pyramid is unusual, being North-East to South-West, as is shown here:  Next, a second capacitor is constructed from 1 mm thick copper sheet. Again, sections of copper pipe can be used after being cut along their long axis and carefully opened out and flattened. This capacitor is just two plates 140 mm x 25 mm spaced 1 mm apart (one inch = 25.4 mm).  A voltmeter can be used to check the exact alignment of the pyramid. There is a video (with a commentary in German here showing an earlier version of this pyramid set-up driving an electrical fan taken from a computer). If this device interests you, then you should join the enthusiast research and development forum mentioned earlier.  In June 2011, Thomas issued instruction videos which show how to construct, use and troubleshoot his newer design of pyramid. These videos are in English and they are very detailed and instructive. One person has split those two very long videos and placed them on YouTube as a series of thirteen smaller videos. In them, he states that the salt water in the design above is actually counter-productive and should not be used.

In June 2011, Thomas issued instruction videos which show how to construct, use and troubleshoot his newer design of pyramid. These videos are in English and they are very detailed and instructive. One person has split those two very long videos and placed them on YouTube as a series of thirteen smaller videos. In them, he states that the salt water in the design above is actually counter-productive and should not be used.